Basic DC Testing Keeps Drones Flying Longer

May 08, 2020

|

Drones or unmanned aerial vehicles (UAVs) are quickly being adopted for commercial and industrial applications, almost as quickly as they have been accepted as part of the modern battlefield for intelligence, surveillance, and reconnaissance (ISR) missions. If major retailers follow through with plans to deliver purchased goods by drone, customers may soon expect to receive delivery of an order in as little as 30 minutes. UAVs and other robotic systems have already proven their value in many different areas, including in farming, in preventing forest fires, even in mapping long runs of power lines for breaks and failures. But what happens to a drone that is losing power? What must be tested, and which are the right instruments to perform the testing? Please join us in the conclusion of this three-part series on testing UAVs; the earlier two blogs explored measurements for maintaining wireless and digital electrical performance in drones.

Some military UAVs (notably for surveillance and higher altitudes) are quite large, with fixed wings and running on liquid fuel and turbine or internal combustion engines. UAVs for commercial and industrial use tend to be smaller, with multiple rotary wings. They typically use multiple brushless DC motors and electrical propulsion systems powered by lithium polymer rechargeable batteries. Different propulsion systems are used in smaller UAVs, with the smallest drones running solely on battery power and DC electric motors typically driving multiple propellers. UAVs with hybrid power systems provide some additional range by using a turbine engine to generate electricity for an electric propulsion system. For these smaller drones, the efficiency of the power supply and the electrical propulsion system is everything and will determine the ultimate flight time and distance for a UAV.

Different UAVs will have different energy requirements depending on applications and expected flight times. Li-ion battery cells are typically used for electrical energy storage within a UAV. Battery packs may be designed for in-flight recharging and the must be kept within safe operating temperatures, voltages, and state of charge. A dedicated CPU within a UAV’s main printed circuit board (PCB) or single board computer (SBC) will typically manage the recharging cycle and process sensor data to ensure proper power measurement and communication with the power system controller.

Regardless of the type of powertrain, power must be efficiently and effectively distributed to the various subsystems within a UAV. Analysis of the power circuitry and power flow throughout a drone, whether starting from a turbo generator, brushless generator, or directly from a rechargeable Li-ion battery, can be performed with a number of different instruments, some quite specialized such as insulation testers for battery cells. DC electrical testing is an essential part of the design and maintenance of commercial, industrial, and military UAVs. By performing regular measurements on a UAV’s electronic speed controller (ESC), for example, the efficiency of the UAV’s powertrain can be better characterized and optimized. Especially in all-electric drones, scheduled measurements can help to maintain the efficiency of an electric UAV’s propulsion system.

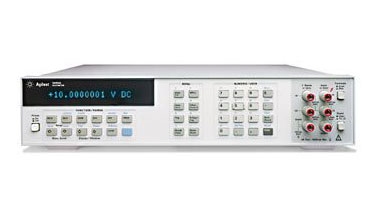

Digital voltmeters and digital multimeters (DMMs) are among the most versatile of test instruments for maintaining UAV electrical system performance. When basic electrical characteristics, such as voltage and current, must be checked, digital voltmeters and DMMs in rack-mount/benchtop format are well suited for laboratory or production-line testing while smaller, battery-powered instruments are a better choice for in-field testing. For example, the Keysight/Agilent 3458A multimeter is clearly much more than “just” a voltmeter. With a GPIB interface for high-speed production testing, it can measure DC voltage from 0.1 to 1000.0 V with outstanding accuracy and stability and with measurement speed to 100,000 readings per second. It can measure DC and AC voltage, AC and DC current, resistance, and even frequency to 10 MHz. It is clearly a production-line measurement tool well equipped for DC voltage/power testing of UAVs on a production line.

In contrast, for the first-time look at the electrical system of a new drone design, the Keithley 2182A Nanovoltmeter provides the high resolution and accuracy for single measurements of extremely low voltages or differences between voltages. It is made for lower voltages, but provides 1-nV resolution for measurements to 10 mV and 10 μV resolution for measurements to 100 V. A second measurement channel delivers 1-μV resolution for measurements to 10 V. The benchtop instrument is designed for laboratory environments. For larger voltages, the model Keithley 2000 6-1/2-digit DMM handles voltages as high as 1000 V DC. For measurements to 100 mV, it provides 0.1-μV resolution and for measurements to 1000 V, the resolution is 1 mV. The benchtop unit boasts 13 built-in measurement functions including current from 10 mA to 3 A and resistance from 100Ω to 100 MΩ.

Design-Stage Testing

At the circuit design stage, when measurement accuracy and confidence in the test results must be the highest, the Fluke 8508A Reference Multimeter provides 8-1/2-digit DC/AC voltage and current measurement precision in a metrology-grade, rack-mount instrument. Its specifications are provided at both 95% and 99% confidence levels. It performs DC voltage measurements within six ranges with maximum limits of 200 mV, 2 V, 20 V, 200 V, and 1000 V. The measurement accuracy is specified within ±0.4 to ±0.7 ppm/°C of a reading across an operating temperature range of +15 to +30°C. It also measures DC current, in six ranges with maximum limits of 200 μA, 2 mA, 20 mA, 200 mA, 2 A, and 20 A. The instrument provides similar accuracy and precision for AC current and voltage measurements.

Of course, such levels of test precision may not be required for UAV production-line and maintenance measurement applications, especially when test capability might be needed in the field. The Keysight/Agilent 34401A is a DMM with 6-1/2-digit resolution that provides reliable measurements of DC and AC voltage and current. It features basic accuracy of 0.0035% for DC measurements and 0.06% for AC measurements and can measure DC voltage to 1000 V and DC current to 3 A. It is essential a medium-sized benchtop DMM with a handle. While it lacks the production-line measurement speed of the Keysight / Agilent 3458A multimeter (see above), it is capable of a respectable 1000 readings/s, which is fine for maintenance-line and in-field measurements on UAV electrical systems.

For in-field power analysis on UAV electrical systems, the Arbiter Systems 931A Power System Analyzer is an easy-to-use instrument that, at a weight of 12.8 lbs (5.8 kg), might be better described as “transportable” than portable. It includes two measurement channels and a large CCFL backlit graphic display to show voltage (to 1000 V), current, phase, frequency, and power with basic accuracy of 0.05% of reading. With a sealed lead-acid battery for 8 h of run time, the analyzer provides plenty of in-field measurement capability, with 8 h also required to recharge the battery for its next series of in-field measurements. With a built-in counter/time to measure elapsed test times, the analyzer can be used as a power trends monitor for in-service UAVs.

Drones and Batteries

As UAVs continue to be designed as smaller units with longer ranges and run times, the pressure is on UAV developers to provide efficient electric drive and storage systems for these drones. Measurement capability to test different battery packs is useful, but so too is an instrument like the Fluke 438-II Power Quality and Motor Analyzer which can troubleshoot power quality in three-phase and single-phase power distribution systems and also check on the performance of electric motors. It is an almost ideal maintenance tool for all-electric UAVs, capable of running in the field for about 16 h on its own lithium-ion rechargeable battery pack. It includes voltage measurement leads and flexible current probes and provides measurements of power, motor speed, torque, power efficiency, revolutions per minute (RPM), and harmonics. It can measure standard electrical power parameters such as voltage, current, power, and harmonic distortion and calculate an electric motor’s mechanical power and efficiency from the electrical measurements.

When motor testing is not needed, Fluke’s 500 series Battery Analyzers, like the BT521 can measure battery voltage as well as resistance. The testers measure DC voltage to 6 V with 0.001-V resolution, to 60 V with 0.01-V resolution, to 600 V with 0.1-V resolution, and to 1000 V with 1-V resolution. The resistance measurement range is 3 to 3000 mΩ, with 0.001-mΩ resolution at the low end and 1-mΩ resolution at the high end.

Additional battery testers include the Chroma 11210 battery cell insulation tester and the Chroma 87001 battery cell simulator. The 11210 provides the means for performing measurements of leakage current and insulation resistance on the rechargeable cells in a drone while the 87001 is a full 16-channel rack-mount system that is designed to replace rechargeable batteries when evaluating UAV performance. It is clearly meant for an experimental environment, when voltage, current, and power characteristics must be tightly controlled to study the effects on drone performance, such as the power consumption of a UAV’s electric motors at different power settings.

To learn more about any of these instruments, or to rent or purchase these or other test equipment, please visit Axiom Test Equipment’s website at www.axiomtest.com to view our inventory. If you would like help selecting the right equipment for your project, contact Axiom Test Equipment’s sales department at sales@axiomtest.com, or call an Axiom sales representative at 760-806-6600.

Back to BLOG