Temperature Chambers Mimic Real-World Conditions

January 02, 2024

.jpg) |

Changing temperatures can impact the operation of an electronic product, degrading performance and reliability. Electronic products are designed for use within specific temperature ranges, according to application, such as aerospace, automotive, commercial, industrial, medical, and military systems. Temperature chambers provide the means of controlling temperatures during testing; a good chamber can adjust temperatures over a wide range and within a tight tolerance. But the value of a temperature chamber is more than setting and maintaining a temperature. Changing temperatures affect electronic performance and practical temperature testing often relies upon having a temperature chamber capable of changing a wide range of temperatures quickly and consistently to duplicate conditions in which a product will be used.

An antenna near a source of heat may endure temperature changes differently than those imposed by sunlight on a rooftop. The same antenna may be required to perform consistently outdoors in winter with freezing temperatures. Understanding the effects that temperature cycling can have on an electronic device can help enhance reliability and avoid temperature-related failures. Characterizing a device under test (DUT) within an environment with well-controlled temperature can provide insights into the DUT’s expected behavior under real-world conditions. Fortunately, high-performance temperature chambers offer wide temperature ranges to match real-world conditions and the capabilities to change temperatures up and down at rates like real-world conditions.

Temperature chambers can be sorted by size, weight, and temperature. Smaller units are ideal for local use, next to a workbench, although the size of their environmental chambers will limit the size and type of DUT. Larger temperature chambers do not have the same placement flexibility, but they can handle larger and more DUTs. Temperature chambers have two key sets of dimensions: for the environmental chamber and for the overall temperature chamber system.

Temperature ranges for temperature chambers meet or exceed widely accepted temperature ranges for electronic applications in various markets, such as 0 to +70°C for commercial products, -40 to +85°C for industrial equipment, and -55 to +125°C for military products. Measurements for the applications and markets usually comply with conditions set forth in well-accepted standards, such as MIL-STD-883 for military temperature testing.

Temperature chambers can be evaluated in terms of their total temperature ranges as well as how fast they can change from one temperature to another and how well they can maintain a temperature once set. The temperature rate of change for a temperature chamber will be affected by whether it is measured with or without a load of some form in the temperature chamber, so it is important to compare the temperature changing capabilities of different temperature chambers under similar load conditions, such as with a stock aluminum load within the temperature chamber. The heat-up and cool-down or pull-down rates of a temperature chamber are determined by the time required to move through a temperature range from a minimum to maximum or from a maximum to a minimum temperature, usually in some number of thermal degrees per minute. Once a temperature chamber has arrived at a final temperature can be measured as some amount of variation in the final temperature as well as the uniformity of the set temperature across the enclosed volume of the temperature chamber. Tight control of temperature enables a temperature chamber to duplicate many of the natural environmental heating and cooling effects to which many outdoor electronic products will be subjected.

Taking Temperatures

Temperature chambers are available with or without computer interfaces for control with an external computer. They often include the capability to control humidity along with temperature. The Test Equity 115A temperature chamber, with humidity capability, has a temperature range of -73 to +175°C. It can maintain a set temperature to a tolerance of ±0.5 dB and uniformity within the temperature chamber of ±1.0°C. Dropping the temperature of the chamber from +85 to -40°C requires 45 minutes or a rate of change of -2.8°C/minute. To change temperature in the opposite direction, the heat-up rate is +5°C/minute. This durable unit features a Watlow F4T temperature controller and 4.3-in. touch-screen display. It is available in benchtop and floor-standing versions, each with temperature-controlled chamber measuring 16 × 12 × 14 in. (406 × 305 × 353 mm). For flexible placement, the benchtop version has external dimensions of 24 × 44 × 26 in. (610 × 1118 × 660 mm) while the floor-standing version measures a deeper 24 × 61 × 26 in. (610 ×1549 × 660 mm).

In a much smaller footprint, which means a smaller temperature-controlled environment, the ESPEC SH-242 temperature chamber measures 17.32 × 27.18 × 27.36 in. (440 × 690 × 695 mm). The tradeoff of its smaller size is in a temperature chamber of 11.81 x 11.81 x 9.84 in. (300 x 300 x 250 mm) and narrower temperature control range of -40 to +150°C. It has a heat-up rate of +3.2°C/min and a cool-down rate of -2.1°C/min across its full temperature range, maintaining a set temperature to a tolerance of ±0.5°C and uniformity within 4°C across the full volume of the temperature chamber. It also features a touchscreen display for local control but adds interfaces such as RS-232C, RS-485, and GPIB for computer control as well as USB and Ethernet ports for data access.

For a larger temperature test environment, the ESPEC BTX-475 temperature chamber provides a chamber measuring 19.6 × 15.0 × 23.6 in. (500 × 380 × 600 mm) with wider temperature range of -70 to +180°C and humidity control. Its external dimensions are 30.25 × 33.50 × 46.0 in. (770 × 850 × 1170 mm). Its larger test chamber than model SH-242 results in different heat-up and cool-down rates of +2.75°C/minute and -2.50°/minute, while maintaining tight tolerance of ±0.5°C for a set temperature.

For faster heat-up and cool-down rates without humidity control, the ESPEC BTZ-4200 offers heat-up and cool-down rates of +15°C/minute and -15°C/minute, respectively, across a temperature range of -70 to +180°C. The temperature-controlled volume is 19.6 × 15.0 × 23.6 in. (500 × 380 × 600 mm) while the temperature chambers full dimensions are 31.0 × 41.5 × 74.0 in. (788 × 1055 × 1880 mm).

Although measurements of the temperature-change rates of many chambers are for an empty chamber, real-world testing involves a load (such as the DUT) within the chamber. It can be useful to know a chamber’s temperature change rates with some form of load. Heat-up and cool-down times for the Test Equity 1027C temperature chamber, are determined with and without an 80-lb. aluminum load in the chamber. This full-sized temperature chamber has a test volume of 40.0 × 32.0 × 36.5 in. (1016 × 813 × 927 mm) in an enclosure measuring 49.00 × 73.25 × 63.00 in. (1244 × 1860 × 1600 mm). It controls temperatures from -73 to +175°C with solid temperature cycling behavior. For an empty chamber, heat-up times are 17 minutes from -40 to +85°C (+7.35°C/minute) and 24 minutes from -40 to +125°C (+6.87°C/minute). With an 80-lb. aluminum load, heat-up times are longer: 29 minutes from -40 to +85°C (+4.31°C/minute) and 42 minutes from -40 to +125°C (+3.92°C/minute), showing the effects of the load. With an empty chamber, the cool-down time is 28 minutes from +85 to -40°C is 28 minutes (-4.46°C/minute). The time for that same drop in temperature is 48 minutes (-2.60°C/minute) with an 80-lb. aluminum load within the temperature chamber.

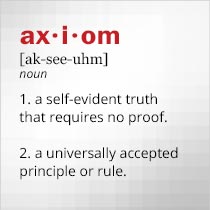

These are some of the temperature chambers described on the Axiom Test Equipment website, with earlier blogs offering additional information: “Considerations in Choosing an Environmental Chamber” and “Keep Temperature and Humidity Under Control.” Temperature chambers come in many shapes and sizes with a variety of features and functions to aid testing many applications, including commercial, industrial, medical, and military products.

Back to BLOG