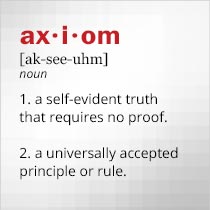

Modular Test Solutions Speed Semiconductor Tests

August 02, 2022

.jpg) |

Semiconductors are often considered “ground-zero” or starting points for advanced electronics technologies, whether for commercial, industrial, military, or medical solutions or even in space. They are fabricated in various configurations and from many materials, each approach yielding a set of characteristics well suited for a variety of applications. Before they can be used, however, semiconductor devices and materials must be full characterized by means of many tests and often over wide measurement ranges. Finding a traditional benchtop test system with enough functionality and performance to characterize some of the latest semiconductor devices and materials can be a challenge. In contrast, a well-designed mainframe that operates according to plug-in modules can not only pack a great deal of measurement power into a small space, but it can also be configured as needed by exchanging modules. Modular semiconductor parameter testers are capable of top-line mainframe accuracy along with the test speed and flexibility for high-volume production-line device testing.

Semiconductor parameter analysis focuses on semiconductor device and process parameters rather than device functions. As detailed in an earlier blog, “Capturing Semiconductor Current and Voltage Characteristics,” parametric analysis explores how essential electrical parameters, such as voltage (V), current (I), and capacitance (C), may change with time or according to different operating conditions. Semiconductor parameter analysis can capture data related to the quality and consistency of a semiconductor substrate material and the devices formed from that material.

The nature of the test stimuli used as part of the parameter measurements will depend upon the type of electrical device being tested, including discrete transistors, integrated circuits (ICs), and most recently system-on-chip (SoC) devices. Semiconductor characteristics must be studied for a variety of ICs, including analog-to-digital converters (ADCs), digital-to-analog converters (DACs), memory devices, microcontrollers, and operational amplifiers (opamps). The test data can also be used for process control monitoring (PCM) and wafer level reliability (WLR) testing when manufacturing semiconductors.

With many measurements to perform and so much data to collect, semiconductor parameter test equipment can grow large and complex. Test Equipment tasked with testing any diversity of semiconductors can face wide ranges in voltage, current, power, and other parameters. A test setup based on traditional benchtop units may require stacks of units, including analyzers, power supplies, and source measure units (SMUs) to provide stimuli. Add interconnecting cables and connectors and test fixtures and the test configurations must be carefully planned for each type of parameter, such as one test layout for C-V measurements and another for I-V measurements. The cables also introduce their own capacitance characteristics which must be considered. When additional measurement capabilities are needed, additional full-sized units are usually required.

Make the Most of Modules

Modular units provide a more “compressed” approach to executing semiconductor parameter measurements. A modular unit consists of a full-sized mainframe and much smaller plug-in modules which contain the measurement capabilities required for a specific semiconductor parametric test. Modular test solutions typically enable quicker, less complicated setups whether performing manual measurements or in an automatic-test-equipment (ATE) environment. For example, modular semiconductor parameter testers can switch between C-V and I-V measurements without rewiring the cables between the test equipment and a device under test (DUT). In a modular tester, it is simply a matter of switching between modules. The smaller size of a total modular semiconductor parameter test setup can speed setup times but also lead to faster test data collection and analysis with much less power consumption. Traditional benchtop and modular testers are both capable of operating with an external computer, usually via GPIB interface, for operational control, but many modular semiconductor parameter testers also contain enough built-in microprocessor power to operate as self-contained measurement systems with simple one-button controls.

As an example, the Keithley 4200A-SCS Parameter Analyzer, starts with a powerful mainframe and allows a user to customize and upgrade the measurement capabilities according to the selection of modules. The mainframe can quickly be ready for I-V, C-V, and pulsed I-V semiconductor device and material characterization and function as a PCM and WLR assistant to help improve semiconductor manufacturing efforts. The modular test solution has the equivalent of a built-in personal computer (PC) which can run the company’s 4200A-SCS Clarius™ test software for precise, automated measurements, even choosing some of those measurements from among hundreds of proven test application examples included with the software.

The 4200A-SCS Parameter Analyzer fits as many as many as nine measurement modules at one time, allowing for a great deal of flexibility and measurement power. It shows results on a bright, 15.6-in.-diagonal touchscreen with 1920 × 1080 pixels resolution and includes many of the interfaces (USB, GPIB, VGA) needed for ATE setups. The mainframe is part of the solution, with the choice of modules determining the measurement power and capabilities.

For lower-power I-V measurements, the Keithley 4211-SMU high-power source measure unit (SMU) provides a current measurement range of ±1 A with 100-fA resolution and a ±210-V voltage range which can be set with 0.2-µV resolution. For higher-power I-V measurements, the Keithley 4210-SMU module has a current range of ±1 A over the same wide ±210 V voltage range. For C-V measurements, simply plug in the Keithley 4210-CVU capacitance-voltage unit and the capabilities for capacitance-voltage, capacitance-frequency, capacitance-time, and AC impedance measurements. This CVU module has a frequency range of 1 kHz to 10 MHz. It can operate with its own ±30-VDC bias supply or draw bias from the ±210 VDC available from another SMU. Include the Keithley 4200A-CVIV I-V/C-V multi-switch module for automated switching between I-V and C-V measurements.

Another example of a modular semiconductor parameter measurement solution is the Keysight B1500A Semiconductor Device Analyzer mainframe from Keysight Technologies which can hold as many as ten measurement modules. It features enough microprocessor power to capture and analyze data without an external PC and show results on a 15-in.-wide touchscreen. The mainframe includes GPIB, USB, and LAN interfaces and a VGA video output port for connection of external displays. It can be equipped with modules for I-V, C-V, and pulsed/dynamic I-V measurements as well as multiple-frequency AC capacitance measurements from 1 kHz to 5 MHz.

As with the Keithley semiconductor parameter tester, the B1500 is supported by an assortment of medium-power source/monitor units (Keysight B1511A MPSMUs) and high-power source/monitor units (Keysight B1510A HPSMUs). Modules such as the high voltage semiconductor pulse generator unit (Keysight B1525A HV-SPGU) provide the capabilities, including TTL trigger outputs, for studying pulsed devices needed in higher-power radar systems. For example, pulses can be set at frequencies from 0.1 Hz to 33 MHz. Pulse periods can be set from 20 ns to 10 s and delays from 0 to 9.99 s with 2.5-ns resolution. With two test channels per module, these plug-in modules enable I, V, and C measurements in constant, free-running, and pulsed measurement modes over wide voltage and current ranges and with high resolution. The B1500’s operation is made more effective and efficient by its versatile EasyEXPERT MS Windows test software. It includes hundreds of applications-based test routines and allows users to automatically store test conditions and measurement results after each measurement as part of a built-in measurement database.

For both mainframes, this is just a small sample of the available modules which can quickly transform a mainframe into a well-equipped semiconductor parameter test solution. More information on the mainframes and the modules can be found by visiting the Axiom website at www.axiomtest.com. And for any help in selecting the right assortment of modules, please contact the Axiom Test Equipment’s sales department at sales@axiomtest.com, or by calling an Axiom sales representative at 760-806-6600.

Back to BLOG