Making Measurements That Keep EVs and HEVs on the Road

May 01, 2018

|

Electric vehicles (EVs) and hybrid electric vehicles (HEVs) are gaining in popularity; seemingly as they gain in the range of each battery charge. Both EVs and HEVs rely on high-voltage batteries and an electric motor; in addition, an HEV is aided by a gasoline engine with its own fuel supply. Both types of vehicles still employ lower-voltage batteries and electrical systems for lights, radios, electric windows, and other voltage-driven functions. Of course, among the key functions in an EV or HEV is charging the high-voltage battery, whether at home or at a remote charging station, and maintaining the efficiency of that battery-charging process. For that reason, test equipment that is capable of emulating the different types of high-voltage batteries used in EVs and HEVs and the charging/discharging cycles of those batteries can be invaluable tools for maintaining the basic performance of an EV or HEV.

Owners of motor vehicles with internal combustion engines learn to almost automatically glance at the gasoline gauge each morning to have an idea of the approximate range of their vehicle before stopping for more fuel. With an EV or an HEV, the fuel is electricity and it is the vehicle’s high-voltage battery and charging system that requires the attention each morning and throughout the day, for a working knowledge of the vehicle’s approximate driving range based on its amount of charge. Of course, an EV or HEV relies on many of the same mechanical parts as a vehicle with an internal combustion engine, such as brakes and front-end steering components. But it is the high-voltage battery and charging system that is arguably the most important part of an EV or HEV and the part of the vehicle that must be steadfastly maintained through regular testing, either by a trusted mechanic or through regular at-home testing.

Electrical tests on an EV or HEV are performed for different reasons, such as to confirm the performance, safety, and environmental soundness of the vehicle, even the electromagnetic compatibility (EMC) of the electronic components and subsystems within the vehicle or the performance of wireless sensors, such as Internet of Things (IoT) devices, within the vehicle. Measurements typically comply with standards established by a number of international organizations, such as the International Organization for Standardization (ISO), le Comite International Special des Perturbations Radioelectriques (CISPR), the Society of Automotive Engineers (SAE), and Underwriters Laboratories (UL) to name a few.

Obviously, the number of different electronic subsystems within an EV or HEV makes complete testing an almost continuous process, especially since electrical performance can change as functions of different variables, such as time and temperature. But access to multiple-function test instruments with measurement ranges that support the evaluation of the high-voltage battery and charging system in an EV or HEV, for example, can provide the type of diagnostic preventive medicine needed to keep an EV or HEV on the road, in the same way as testing the standard automotive (12-V) battery and starter in a conventional vehicle with internal combustion engine using a battery-powered digital multimeter (DMM).

The Yokogawa DL350 ScopeCorder is one such measurement tool that can perform a number of different tests on different electrical systems within an EV or HEV, including the high-voltage battery and charging system. While fully portable, it is somewhat more complex (but also more capable) than a DMM and is perhaps best thought of as a portable oscilloscope or waveform recorder with memory. It works with plug-in modules which define its measurement capabilities, with 18 modules to choose from. The instrument can perform measurements on as many as 32 different channels, useful capability given the many different electrical subsystems within an EV or HEV.

The Yokogawa DL350EV is a special version for EV and HEV testing, with 8 available slots for plug-in function modules; it can perform simultaneous voltage and current measurements. It can be configured for as many as 128 channels (depending upon choice of plug-in modules) to tackle the large number of electrical subsystems within an EV or HEV. The different versions of ScopeCorders essentially bring laboratory-grade measurement capabilities to the field, with the capability of performing long-term measurements and storing test results over time to plug-in SD memory cards. Results are shown on a 10.4-in. TFT color LCD screen.

The NHR 9200 Series Battery Module/Pack Test Systems from NH Research are among the more flexible test instruments for evaluating the health of an EV or HEV high-voltage battery and charging system. The programmable testers can perform automated characterization, power cycling, and life-cycle testing of high-voltage battery modules and packs, with the flexibility of built-in digital measurements and oscilloscope displays. These test systems provide the measurement ranges and capabilities to evaluate all high-voltage battery chemistries, including lead-acid (Pb-acid), nickel-cadmium (Ni-Cd), and lithium-ion (Li-ion) batteries and their charging systems.

These environmentally sound testers allows a great deal of energy typically lost from an EV or HEV battery during discharge testing to be recycled through a test facility’s AC power grid. As an example of a particular model’s capabilities, the model NHR 9200-4960 has a charging range of 0 to 600 V with power-handling capability of 8 kW and current capacity of 40 A. Its discharging capabilities include 10 to 600 V, 12 kW power, and 40 A current. This instrument can be programmed for automatic measurements with high accuracy, such as 0.1% for voltage, 0.2% for current, and 0.4% for power. The tester can even set resistance from 0 to 500 Ω as needed for emulating resistor components, with 2% accuracy.

Precision AC testers such as the Chroma 61511 and 61512 programmable AC power sources provide the means to simulate a wide range of AC line conditions during EV and HEV testing, with power ratings of 12 and 18 kVA, respectively, and high-voltage tuning ranges of 0 to 300 V with 0.2% accuracy. The single-phase test sources offer maximum RMS currents of 96 and 144 A, respectively, with peak current capabilities of 384 and 576 A, respectively.

California Instrument’s MX45-3PI is an AC/DC power supply system well suited for frequency conversion testing as well as automatic-test-equipment (ATE) applications such as EV and HEV charge/discharge testing. Capable of as much as 135 kVA power with as much as 400 V voltage, this is a highly programmable tester, with a diversity of computer interfaces: Ethernet, GPIB, RS-232, and Universal Serial Bus (USB) ports. This flexible tester can operate in single- and three-phase modes and even contains an arbitrary waveform generator for producing test waveforms as needed.

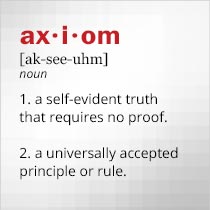

This is a small sample of the number of different electrical measurement instruments available for EV and HEV testing on the Axiom Test Equipment website. As the driving range of EVs and HEVs and their high-voltage batteries and charging systems is constantly increasing, so, too, is the popularity of these environmentally sound vehicles. At the same time, the need to measure and maintain the batteries and electrical systems within these vehicles is also growing. Fortunately, measurement solutions are available for rent or sale by visiting Axiom’s website at www.axiomtest.com, contacting Axiom Test Equipment’s sales department at sales@axiomtest.com, or by calling an Axiom sales representative at 760-806-6600. For more EV's resources and equipment used in EV Testing visit our EV / HEV industry page.

Back to BLOG